Water Turbines

- Water Turbines

- Stationary Curved Vanes

- A Series Of Moving Curved Vanes.

- Turbine With Curved Vanes And An Inward Radial Flow (francis Or Gerard Turbine)

- Efficiency Of Turbines

- Impulse Turbine Allowing For Friction

- Reaction Turbines

- Characteristic Curves And Iso-efficiency Curves For A Turbine Under All Operating Conditions

- Page Comments

Water Turbines

Hydro electricity is a reliable form of renewable energy. Water turbines are highly efficient and easily controlled to provide power as and when it is needed. In addition, the only system currently available to store large quantities of electrical power is pumped storage.General Approach To Find Force, Work Done, Efficiency, Etc.

- Find the mass of liquid/sec. striking the vanes ( slugs/sec or kilograms/sec).

- Find the change in absolute (or relative) velocity of the liquid in the required direction. (ft/sec. or meters/sec.)

- Force on the vane in this direction (Newton's second Law) equals mass/sec

change of velocity. ( slugs/sec

ft/sec = lb. or kg/sec

mtr./sec = Newtons)

- The vane exerts an equal and opposite reaction on the liquid and the supply nozzle. (Jet reaction)

- Work done / sec. by the liquid on the vane is the vane velocity

force on plate in the direction of the velocity. (ft.lb./sec. or Watts)

- Horse Power output = Work done per sec.

- Efficiency,

= Output Power/ Input power from jet

Series Of Moving Plates

MISSING IMAGE!

23287/Intro-to-Turbines-001.png cannot be found in /users/23287/Intro-to-Turbines-001.png. Please contact the submission author.

- The weight of water hitting the plates per second

. N.B. For a single plate the weight of water per second striking the plate is

- The change of velocity =

- Force on plate = mass/sec.

Change of velocity

- Work done/second = Force

Velocity

- The input = the Kinetic energy of the jet

- The efficiency of the system,

- For a given jet velocity,

- For maximum

,

and the value of the maximum efficiency

.

A Single Plate Inclined To The Jet.

MISSING IMAGE!

23287/Intro-to-Turbines-002.png cannot be found in /users/23287/Intro-to-Turbines-002.png. Please contact the submission author.

- The weight of water striking the plate per second will be, as before, given by:

- Change of velocity normal to the plate =

- Normal force on plate

- Component of

in the direction of

- Work done on plate

Stationary Curved Vanes

MISSING IMAGE!

23287/Intro-to-Turbines-003.png cannot be found in /users/23287/Intro-to-Turbines-003.png. Please contact the submission author.

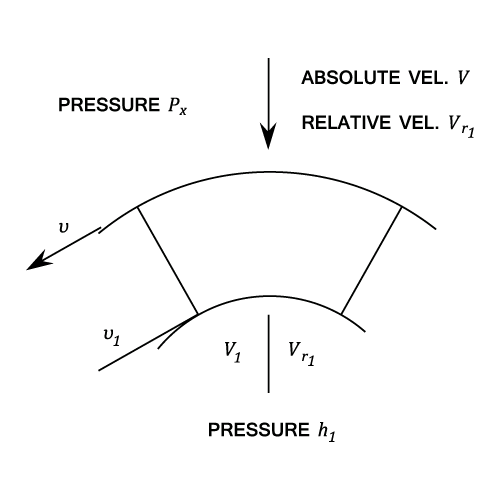

A Series Of Moving Curved Vanes.

Absolute velocity is the vector sum of the velocity of a fluid parcel relative to the earth and the velocity of the parcel due to the earth's rotation

Relative velocity and is tangential to the blades.

Blade velocity (Add to

)

Absolute velocity and the vector sum of

and

.

The velocity of whirl (Component of

in the direction of

)

The velocity of flow (Component of

normal to direction of

)

The suffix 1 refers to the outlet triangle.

Low Speed

MISSING IMAGE!

23287/IR-Turbines-004.png cannot be found in /users/23287/IR-Turbines-004.png. Please contact the submission author.

High Speed

- The outlet triangle remains the same but the inlet triangle is now:

Note:

MISSING IMAGE!

23287/IR-Turbines-007.png cannot be found in /users/23287/IR-Turbines-007.png. Please contact the submission author.

and

if there is no friction

Pelton Wheel (circumferential)

- The two velocity triangles are for low and high flow (the inlet triangle is a straight line):

For both types of flow above:

MISSING IMAGE!

23287/IR-Turbines-pl.png cannot be found in /users/23287/IR-Turbines-pl.png. Please contact the submission author.

- Jet velocity

, where

is the head behind the nozzle and

is the Velocity coefficient.

- Weight of water per second

- The blade speed,

- Force on the vanes = mass of water/second,

- Change in velocity

- Work done on the vanes = Force

Velocity

- The Kinetic energy supplied

- The efficiency,

= Work done / K.E. supplied

For a Pelton Wheel Only(if friction is ignored)ButFor the maximumat a given head and blade angle:

Which occurs when

i.e. The bucket speed is half the jet speed. This is a theoretical figure and in practice, due to frictional losses, the maximum efficiency is when - Jet velocity

Example - Example 1

Also

Work done per second on the vanes = The force in the

- The efficiency of the turbine is

Turbine With Curved Vanes And An Inward Radial Flow (francis Or Gerard Turbine)

The following diagram shows the velocity triangles for both low and high speed.MISSING IMAGE!

23287/IR-Turbines-radial.png cannot be found in /users/23287/IR-Turbines-radial.png. Please contact the submission author.

- Let the weight of water/second striking the vanes be

lb/sec.

- Tangential momentum/second at entry

- Moment of momentum at entry

- Moment of momentum at outlet

- Torque on the vanes equals the change of moment of momentum per second

Efficiency Of Turbines

Impulse Turbines (No allowance for frictional losses)MISSING IMAGE!

23287/Efficiency-of-Turbines-004.png cannot be found in /users/23287/Efficiency-of-Turbines-004.png. Please contact the submission author.

Impulse Turbine Allowing For Friction

MISSING IMAGE!

23287/Efficiency-of-Turbines-005.png cannot be found in /users/23287/Efficiency-of-Turbines-005.png. Please contact the submission author.

Example - Example 1

( one Horse Power (HP) is 550 ft.lb/sec. One cubic ft. of water weighs 62.4 lb.,

Neglecting windage losses, find:

- a) The efficiency of the runner.

- b) The diameter of each jet.

- a) The efficiency of the runner is

- b) The diameter of each jet is

or approx.

inches.

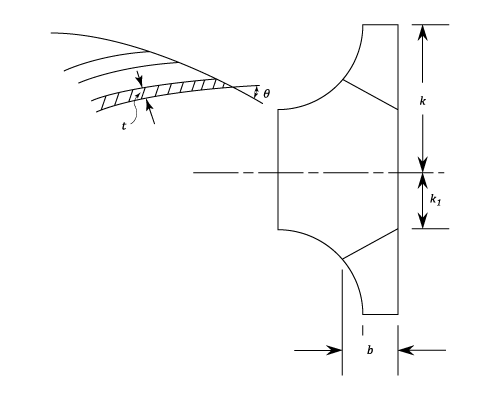

Reaction Turbines

Inward radial flow, mixed flow, or axial with a propeller shaft. They may be sited below the tail race or above it with a draft tube.MISSING IMAGE!

23287/Efficiency-of-Turbines-002.png cannot be found in /users/23287/Efficiency-of-Turbines-002.png. Please contact the submission author.

The absolute velocity at the entry of the runner

The absolute velocity at the exit of the runner

the head.

- For a Reaction Turbine

- For Axial Flow

. For radial flow

- Velocity of Flow

- Let

be the number of blades,

the blade thickness and

the width of the

Variations Of Pressure Head Across The Turbine Passage. Assuming No Losses

Example - Example 1

The runner is 24 inches outside diameter and 16 inches inside diameter and the widths at the entrance and exit are 2 and 3 inches respectively.

The pressure at entry to the guides is + 87 ft.head and the kinetic energy there can be neglected. The pressure at discharge is - 6 ft.head.

If the losses in the guides and moving vanes are taken as

- a)The speed of the runner in r.p.m. for tangential flow on to the running vanes

- b) The horse-power given to the runner by the water.

- a)The speed of the runner is

- b) The horse-power given to the runner by the water is

Kilo watts

Specific Speed Of A Turbine

- Geometrically similar - made from the same drawings but to a different scale.

- Dynamically similar - Operating conditions and equal efficiencies.

MISSING IMAGE!

23287/SpecSpeed-and-Unit-Conditions-0006.png cannot be found in /users/23287/SpecSpeed-and-Unit-Conditions-0006.png. Please contact the submission author.

Notes On Specific Speed

is based on the values of

,

, and

used at the design point. i.e. At maximum efficiency.

is NOT dimensionless and there are different values in each of the measurement systems.

- Unless otherwise stated,

is in r.p.m.

is in Brake Horse Power(b.h.p.) (

)

- The unit of

are

can be made dimensionless and still be a constant by dividing by

and this is called the Speed Number

- For a particular type of Turbine

is constant.

Thereforeor

(constant) but

Efficience

Therefore

andfor different types of Turbine and a comparison of heads for a particular power and speed.

The head requirements for a turbine to develop 100 b.h.p. at 1000r.p.m.- For a Pelton Wheel

Head required 520 ft.

- For a Turgot Turbine

Head required 335 to 180ft

- For a Francis Turbine

Head required 180 to 40ft

- For a Propeller Turbine

Head required 40 to 23ft

- An example of the use of Specific Speed

What turbine would be used if there was a supply of 10 cu.ft/sec under a head of 225 ft. ? Assume an efficiency of 80%. Power Output = Water h.p.inputEfficiency

It would therefore be necessary to use a Turgot Turbine. However it might be possible to use a Pelton Wheel with two jets. Power per jeth.p. Therefore

per Jet

Try a Pelton Wheel with four Jets:per Jet

This would be a practical proposition but would result in some loss of efficiency due to interference between the jets. A better alternative would be to have two wheels on the same shaft with two jets per wheel.

Unit Conditions

- Unit Speed

- Unit quantity of a Turbine is the flow through the turbine when operating under a head of one ft. assuming similar conditions.

- Unit Power of a given turbine is the power output of the turbine when operating under a head of one ft. assuming no change in efficiency

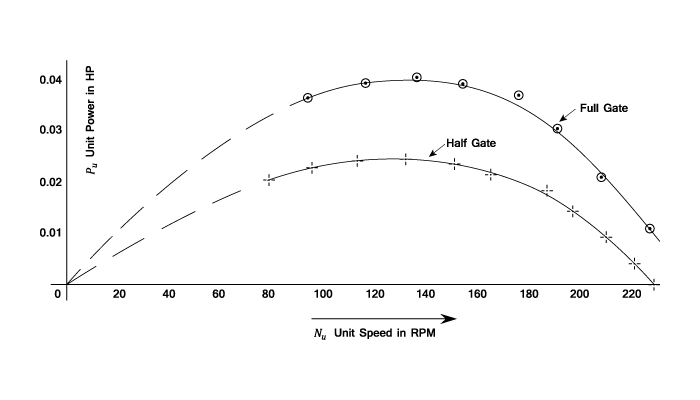

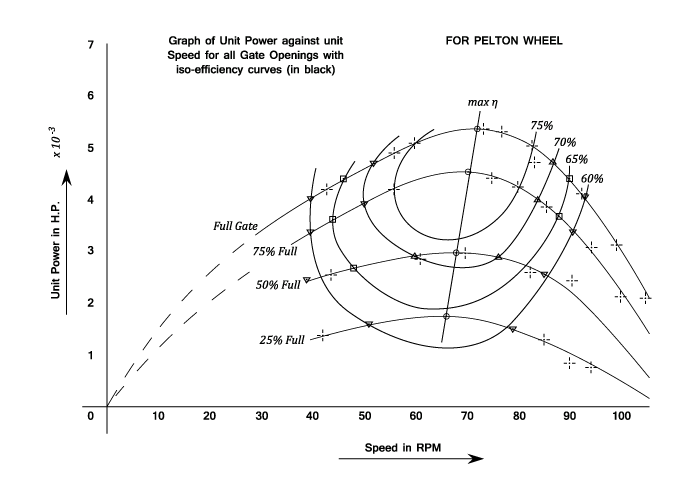

Performance Curves Of A Turbine.

- These are plotted for a constant head and a constant Gate opening ( Or needle valve setting) and are on the basis of speed in r.p.m.

MISSING IMAGE!

23287/SpecSpeed-and-Unit-Conditions-0012.png cannot be found in /users/23287/SpecSpeed-and-Unit-Conditions-0012.png. Please contact the submission author.

Characteristic Curves And Iso-efficiency Curves For A Turbine Under All Operating Conditions

The Turbine is tested under a constant head

But since

And

Substitute for

Or substitute for

Power,

From Equation (146),

From Equation (148),

i.e.

From equations (144) and (150)

These seven expressions allow the performance of the prototype turbine to be estimated from tests on the model. Note that there are in fact only three independent equations.

The efficiency predicted for a large Turbine from test carried out on a model is usual lower than that obtained from the actual prototype. This is because of the relatively greater frictional losses in the smaller passages of the model.

Strictly speaking the surface finish of the model should be geometrically similar to that of the prototype. The reduction in efficiency is said to be due to scale effects and is corrected for in practice by the use of empirical equations such as:

Example - Example 1

At what speed must the model be run and if it develops 135 h.p. and uses 38cu.ft.of water per second at this speed, what power will be obtained from the full scale Turbine, assuming that it's efficiency is 3% better than that of the model?

- The specific speed is

- The power is

Login

Login