Engineering › Materials ›

Torsion

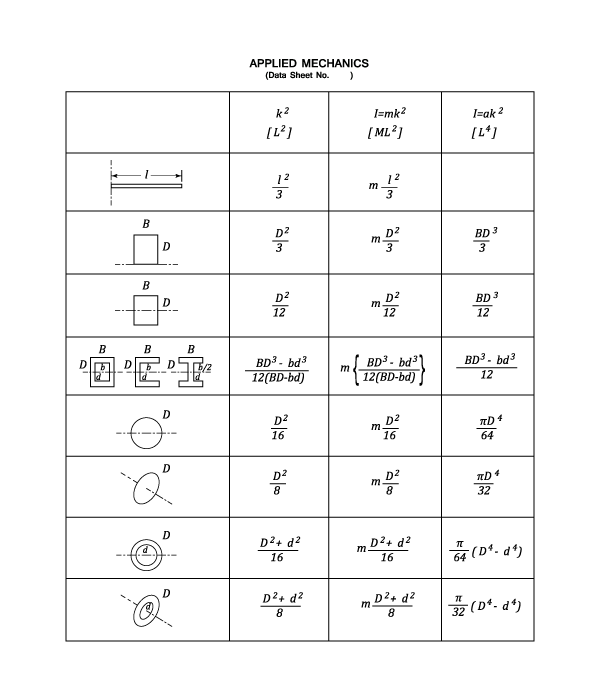

The relationship between torsional forces, shear strain and polar moments of inertia.

Contents

Introduction

Torsion occurs when an object, such as a bar with a cylindrical or square cross section (as shown in the figure), is twisted. The twisting force acting on the object is known as torque, and the resulting stress is known as Shear stress. If the object undergoes deformation as a result of and in the direction of the application of the force, the resulting deflection is known as Strain. Twisting a simple piece of blackboard chalk between ones fingers until it snaps is an example of a torsional force in action. A common example of torsion in engineering is when a transmission drive shaft (such as in an automobile) receives a turning force from its power source (the engine).

Circular Shafts

When a pure torque acts upon a shaft, shear stresses will be set up which act in directions perpendicular to the radius at all points. The complimentary shear stresses on longitudinal planes will cause the distortion of filaments which were originally in the longitudinal direction. Assume that the points lying on a radius before twisting will remain on that radius, and that the angle of twist is

Example 1

- Compare the weights of equal lengths of hollow and solid shaft to transmit a given torque for the same maximum shear stress, if the inside diameter is 2/3 of the outside. From equation (7) for a solid shaft: and or If the torques on both shafts are equal The ratios of equal lengths =

Thus the ratio of the weight of the hollow shaft to that of the solid shaft

Combined Bending And Twisting.

This occurs frequently in practice when a shaft is subjected to both bending and inertia forces. Stresses are set up due to gravity, torque, and shear forces, although the latter is usually unimportant since its maximum value occurs at the neutral axis where the bending stress is zero. For the purposes of design it is necessary to calculate all the principle stresses( maximum shear stress, shear strain energy etc.) so that these can be used to compare them with the criterion of failure. IfExample 2

- A flywheel weighing 1200lb. is mounted on a shaft 3in. in diameter and midway between two bearings 24in. apart. If the shaft is transmitting 40 h.p. (1 h.p. = 550 ft.lb./sec)Calculate the maximum shear stress at the end of a vertical and horizontal diameter in a plane close to the flywheel. At the ends of a vertical shaft use equation ( ) thus on the "tension" side of the shaft the principle stresses are 3250 lb./sq.in. in tension and 528 lb./sq.in. compression. On the "Compression side the principle stresses are 3250lb./sq.in. in compression and 528lb./sq.in. in tension. From equation ( ) the maximum shear stress is given by:- At the end of a horizontal diameter the bending stress is zero and the torsional shear stress has a value. This is a pure shear stress and the principle stresses are

, the maximum shear stress being 1320 lb./sq.in.

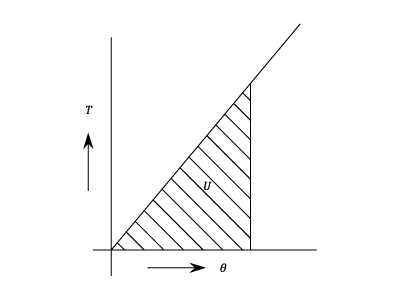

Strain Energy In Torsion.

When a shaft of length l is gradually twisted through an angle

Login

Login